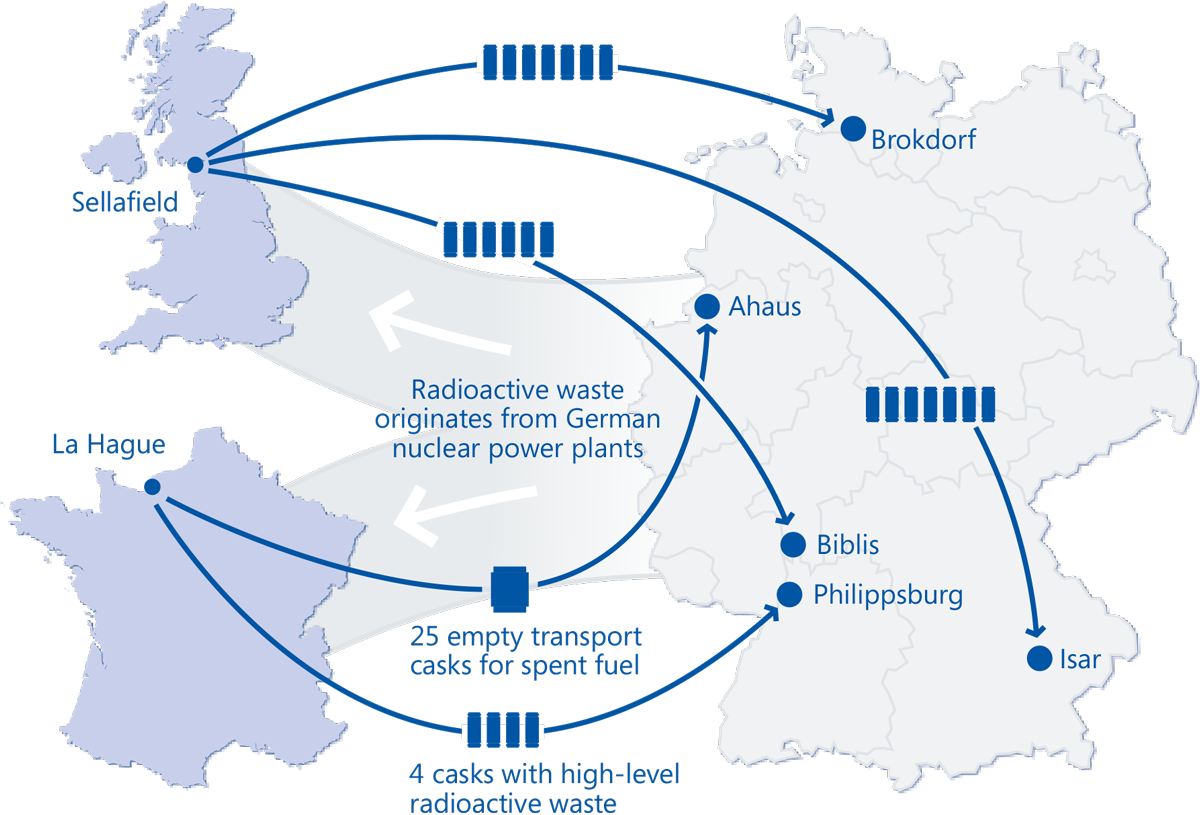

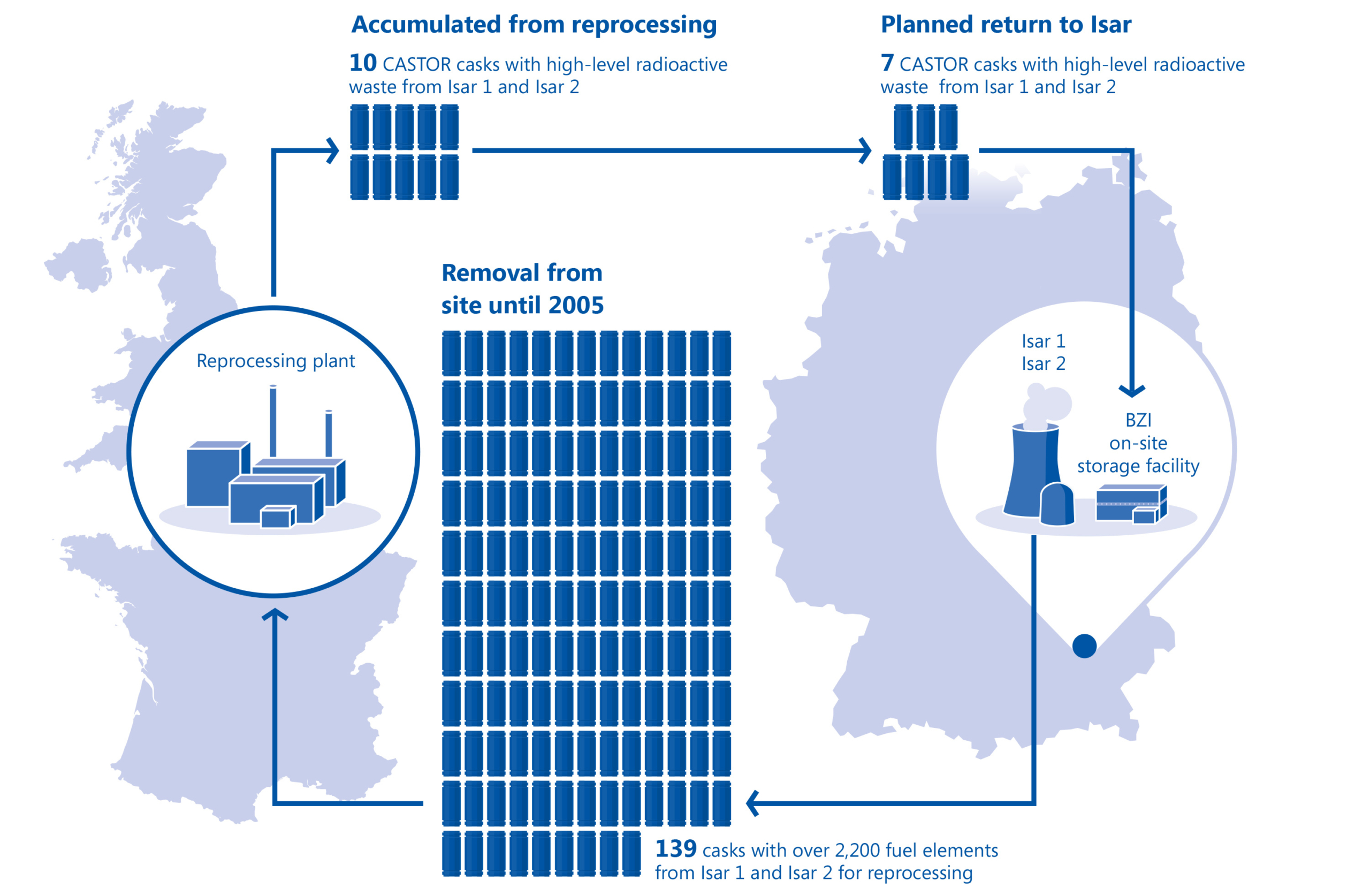

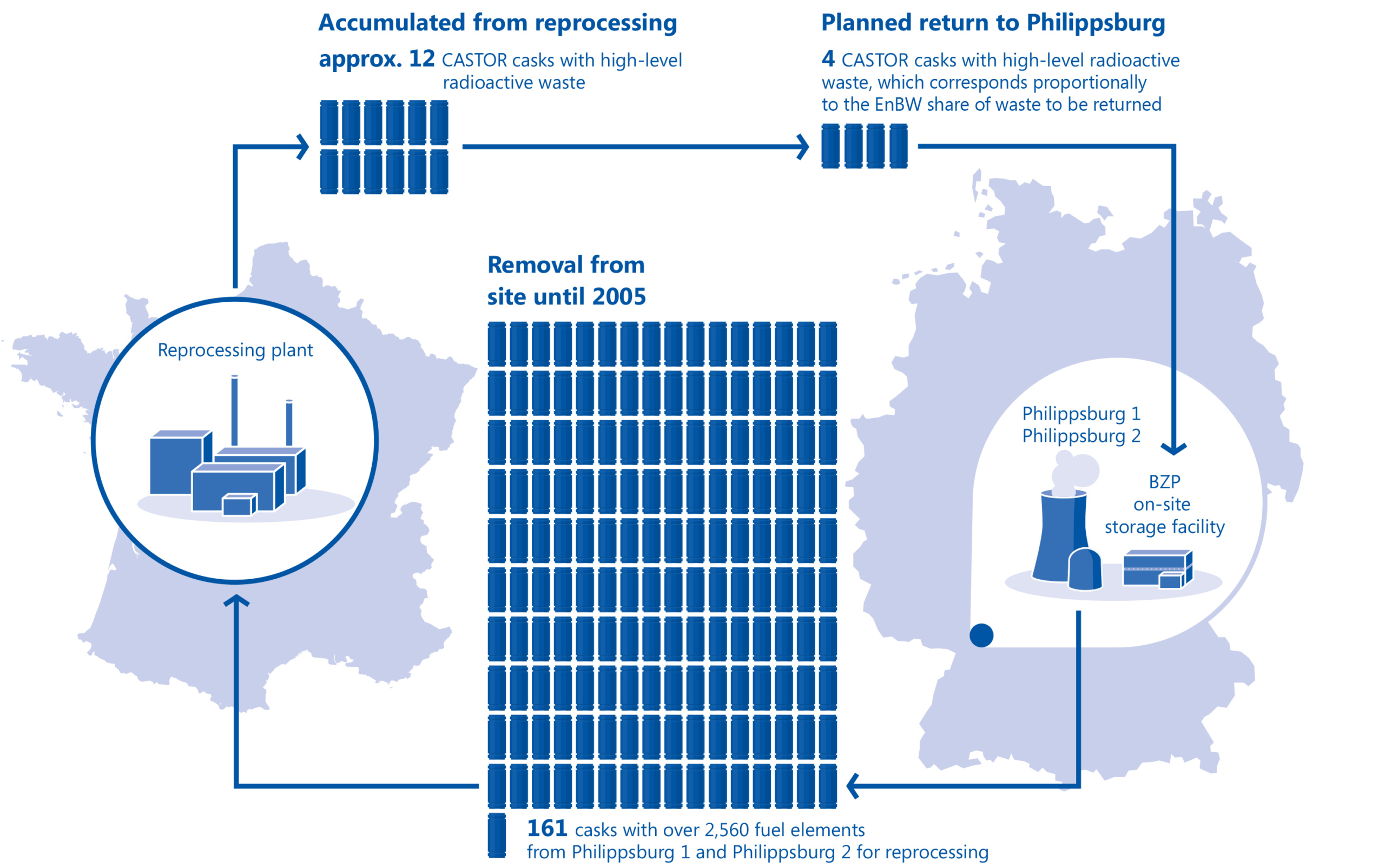

Until 2005, fuel elements from German nuclear power plants were transported for reprocessing to the United Kingdom and France. Most of the resulting high-level radioactive waste, which originated in Germany, have already been transported back to Germany. 18 casks with vitrified high-level radioactive waste are now ready to be returned to Germany. These casks will be stored in the Brokdorf, Isar and Philippsburg interim storage facilities. In November 2020 six casks with vitrified high-level radioactive waste from reprocessing in the United Kingdom were transported to the Biblis interim storage facility. The casks will later be taken from these four facilities to a repository or to a nearby conditioning plant.

This high-level radioactive waste originates from German nuclear power plants. The nuclear power plant operators have had the fuel elements reprocessed abroad. Germany is committed to taking back this waste and returning it to the waste producers.

Reprocessing abroad was the usual disposal procedure prior to 2005 and up to 1994 was in fact mandatory.

The transport of German fuel elements for reprocessing in other countries has been prohibited by law since 2005. Nonetheless, reprocessing waste was still in storage abroad. Waste owners, i.e. the operators of nuclear power plants, are contractually required to accept the return of their radioactive waste to Germany. The Federal Republic of Germany is also bound under international law to take back this waste.

Reprocessing of fuel elements

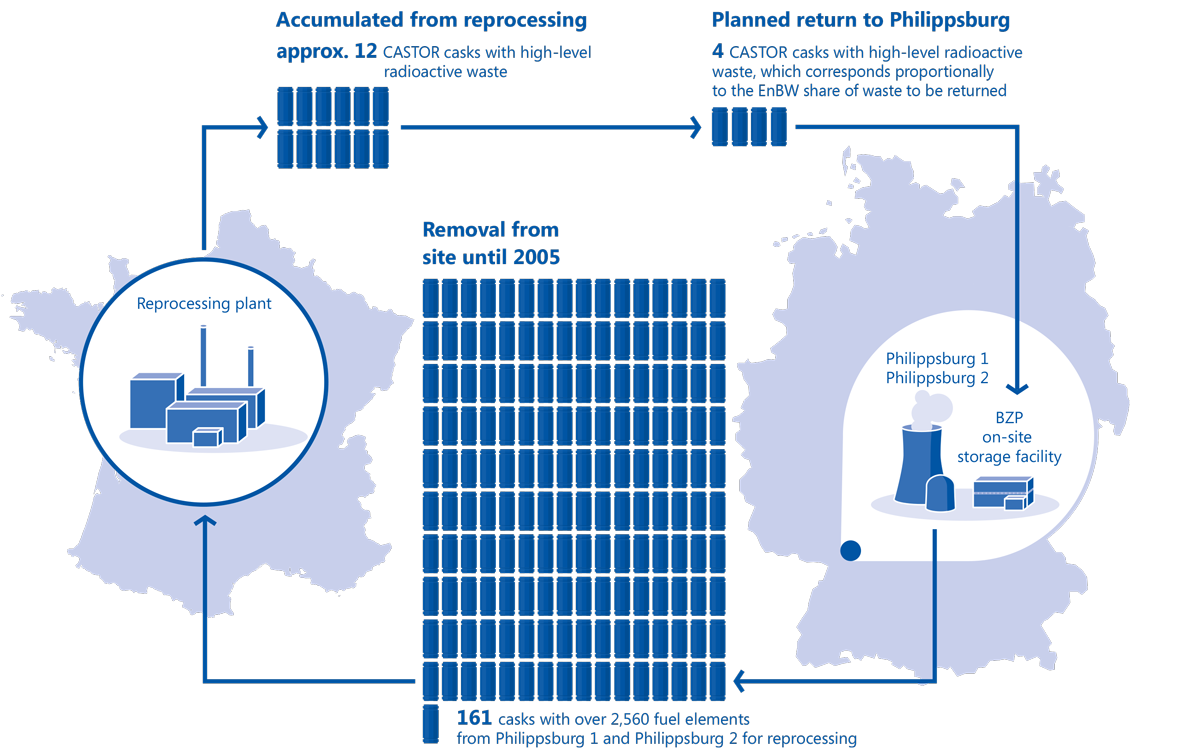

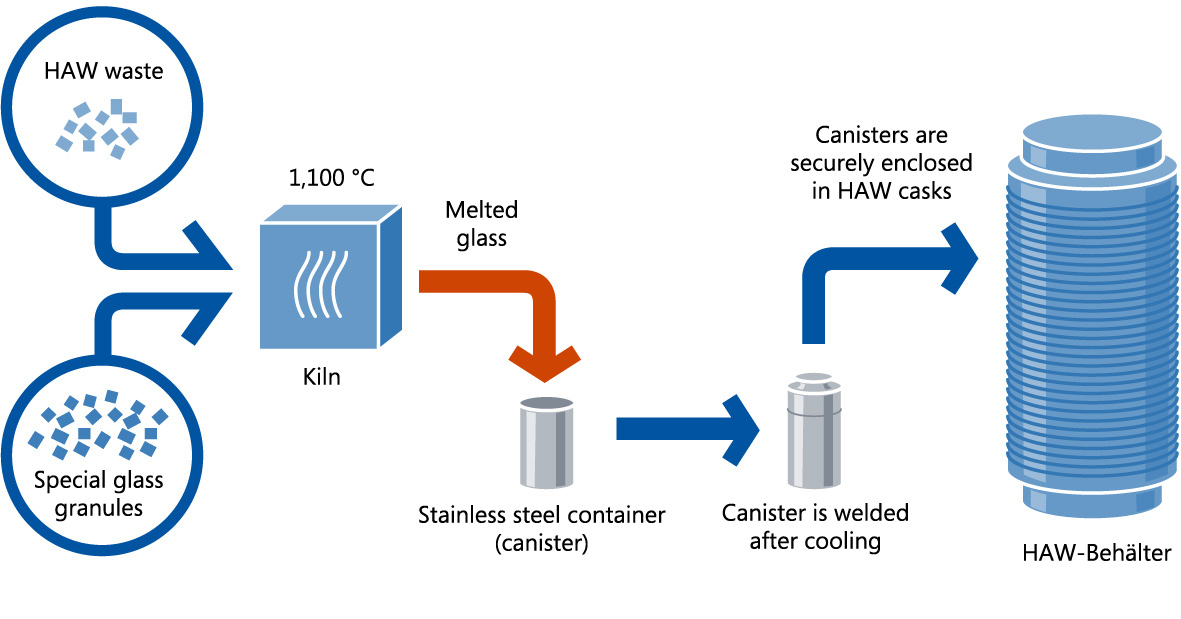

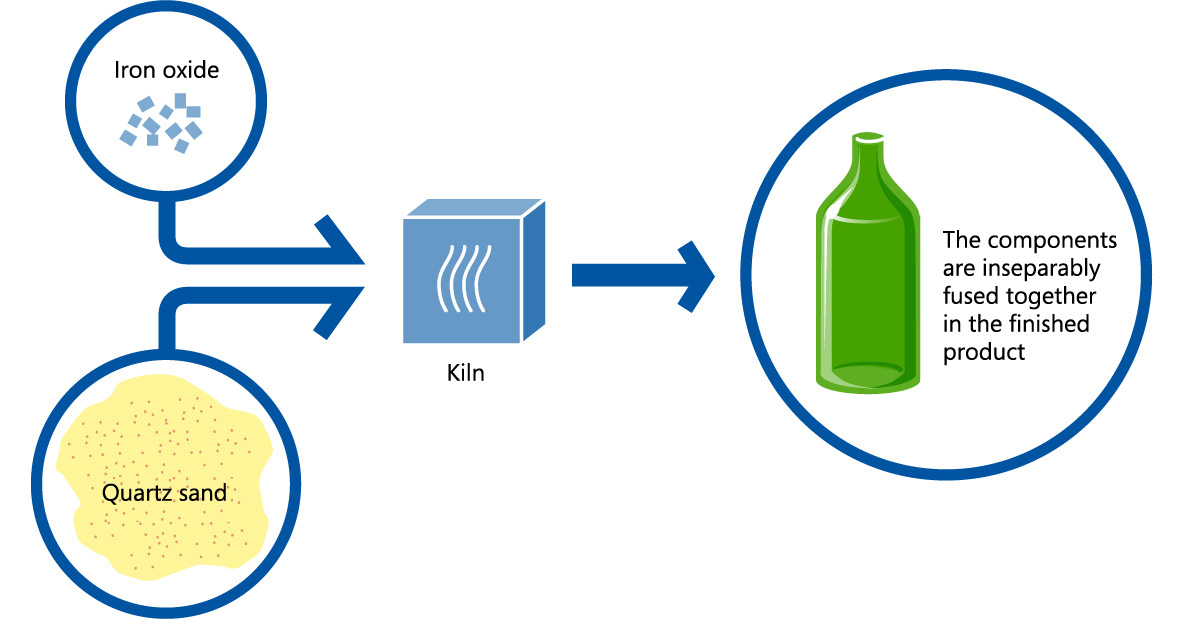

Nuclear power plants run on radioactive materials, so-called “fuel elements”. These fuel elements are depleted after several years of operation and are replaced. In the past, the operators of German nuclear power plants transported their fuel elements to La Hague (France) and Sellafield (United Kingdom) for reprocessing. During reprocessing, spent fuel elements are reduced mechanically (decladding) and separated chemically into recycled nuclear fuel material and radioactive waste.

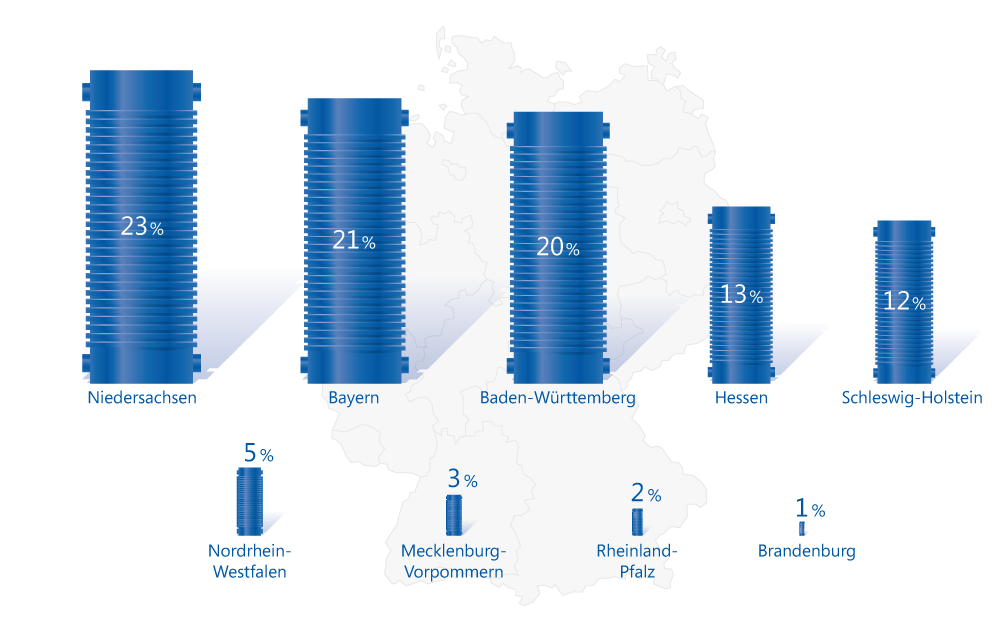

A new consensus: fair regional distribution

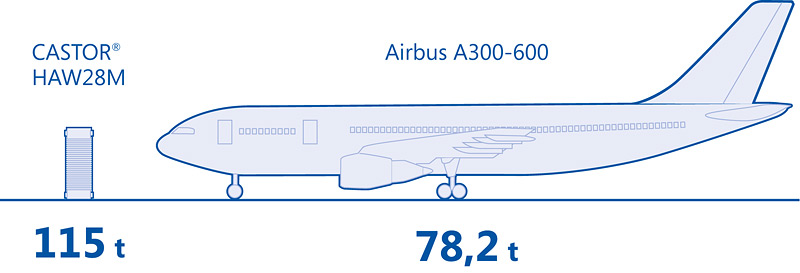

Up to 2011, 108 CASTOR casks holding high-level radioactive waste from the reprocessing plant in La Hague were returned to the interim storage facility in Gorleben. Six CASTOR casks holding high-level radioactive waste from the reprocessing plant in Sellafield were transported to the Biblis interim storage facility in November 2020. Another 18 CASTOR casks will have to be returned to Germany in the next few years.

A new bilateral agreement between Germany and France, which was agreed upon in 2021, amends the return concept that was decided in consensus between the Federal Government, all participating federal state governments and the nuclear power plant operators: According to that and amongst other things, 25 empty spent fuel casks should be transported from the reprocessing plant in La Hague to the Ahaus interim storage facility. The fundamentals of the return concept are unaffected by this new amendment.

Concept for return

The relevant nuclear energy law stipulates that the remaining 25 casks can no longer be moved to the Gorleben interim storage facility but must in future be stored in on-site interim storage facilities. In 2015, the Federal Ministry for the Environment submitted a return shipment concept which provides for the fair distribution across the whole of Germany of waste from reprocessed German fuel elements which is still in storage abroad. A broad consensus was reached on the four sites to which radioactive waste will be returned: Biblis in Hesse, Brokdorf in Schleswig-Holstein, Isar in Bavaria and Philippsburg in Baden-Württemberg. Six CASTOR casks holding high-level radioactive waste from reprocessing were already returned to the Biblis interim storage facility in November 2020.

There is agreement on this between the Federal Government, all participating federal state governments and the nuclear power plant operators as waste producers who are and remain responsible for the return shipment of the waste generated by them. The previous operators of the interim storage facilities submitted applications for the four on-site interim storage facilities. BGZ has managed the applicable nuclear licensing procedures since 1 January 2019. It has now been decided which interim storage facilities will store high-level radioactive waste from German nuclear power plants until it is transferred to the repository. The interim storage facilities, in which high-level radioactive waste is already being stored in the form of irradiated fuel elements from each of the nuclear power plants, are technically equipped to store these casks.

In its “Overall concept for the return of vitrified radioactive waste from reprocessing” of 19 June 2015, the Federal Ministry for the Environment concluded that: “The prerequisites for returning casks of vitrified wastes from reprocessing to Germany have been fulfilled. The storage of these casks is technically feasible and legally possible. The instructions on the general requirements for technical and legal issues and procedures apply to […] all interim storage sites that are planned to be used.”